Reinforced Promotion Business

Cleaning agent (purging pellet) business for plastic molding machine market

Cleaning agent (purging pellet) business for plastic molding machine market

Improve your product quality and work-efficiency with our innovative purging pellet

Koshida’s new business for supporting the plastic molding industry

For producing higher quality plastic products more efficiently

Koshida strongly supports customers who continue to challenging to supply high quality plastic products with this innovative purging pellets.

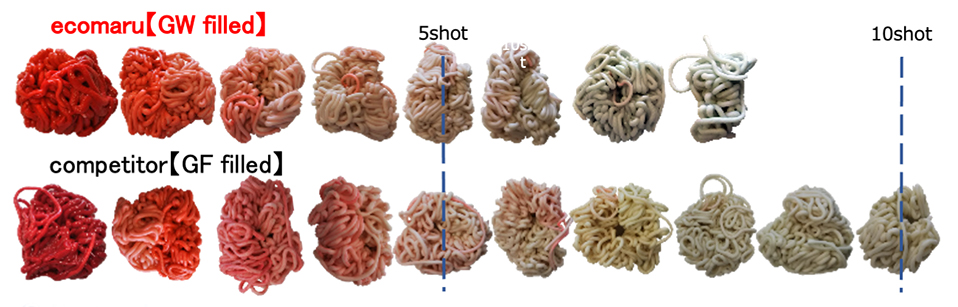

"ecomaru" is the purging pellets for mixing Glass wool (GW: short glass fiber) for the first time in the World.

"ecomaru" helps to reduce the defective rate dramatically and improve the productivity in molding work by the overwhelming detergency that ecomaru generates cannot be obtained from the other purging agents.

※:Number of patents registered in Japan: 9, over 12 foreign countries: 22, in EU: 3, for PCT international applications: 2

【World First※】"ecomaru" purging pellet containing glass wool with high detergency itself

※:purging agent for plastic molding machine market (according to NANODAX CO., Ltd.)

【World First※】"ecomaru" purging pellet containing glass wool with high detergency itself

※:purging agent for plastic molding machine market (according to NANODAX CO., Ltd.)

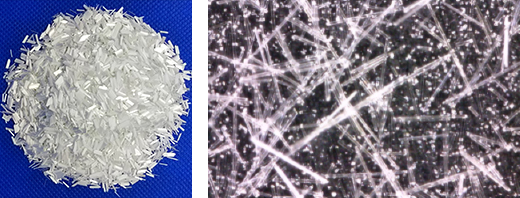

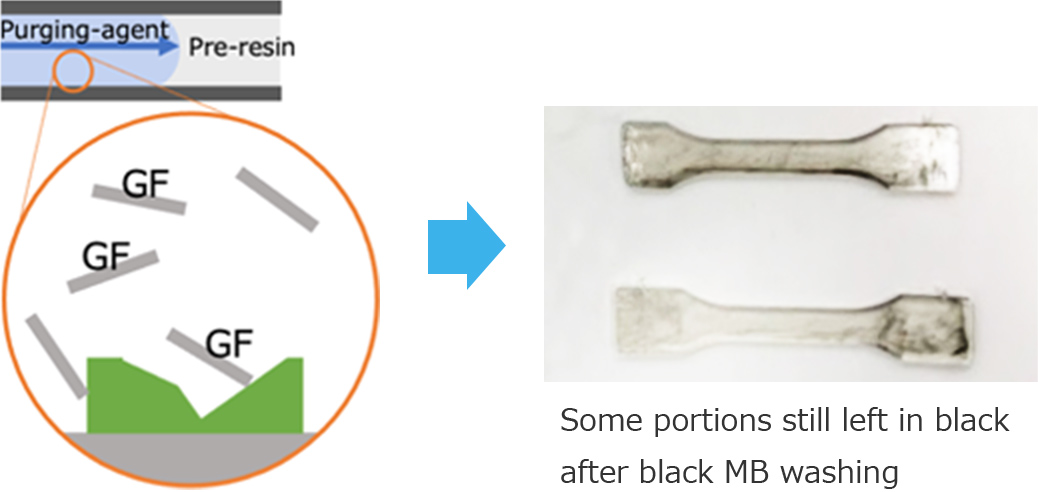

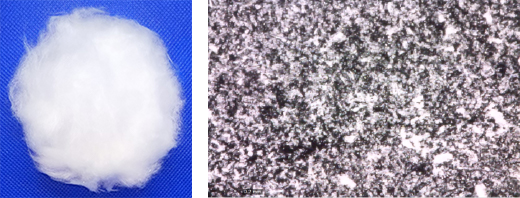

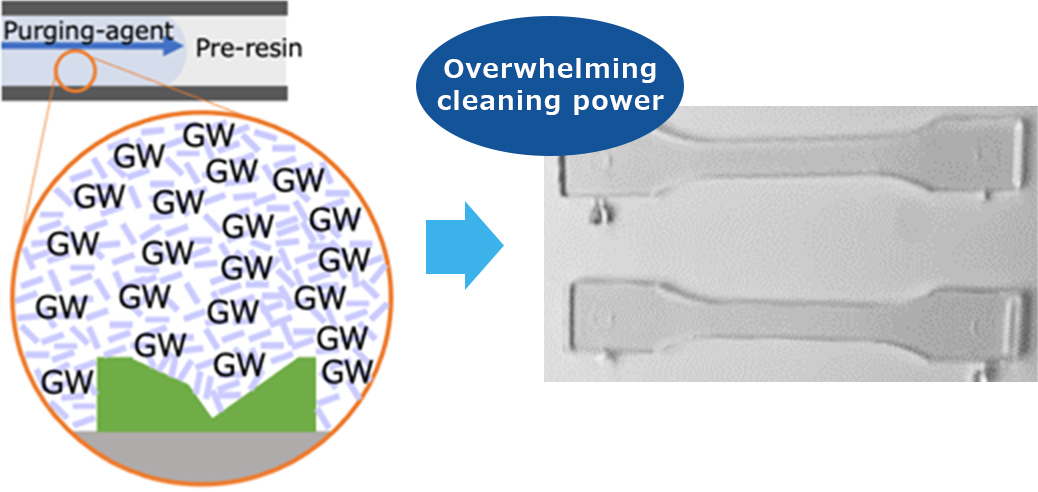

Short and thin glass wool is mixed in "ecomaru." Its overwhelming detergency compared to that of conventional purging agent is achieved from removing unnecessary materials by countless number of micro glass wools having large specific surface area.

Conventional purge agents

GF

GF

| Fiber length | approx. 0.8 mm (long) |

| Fiber diameter | approx. 11㎛ (thick) |

Cleaning with a small number of long formed GF

ecomaru

GW

GW

| Fiber length | approx. 0.06mm (short) |

| Fiber diameter | approx. 4 to 6 microns (thin) |

Cleaning with numerous number of short formed GW

Advantages for "ecomaru"

- Significant reduction of the defective rate

-

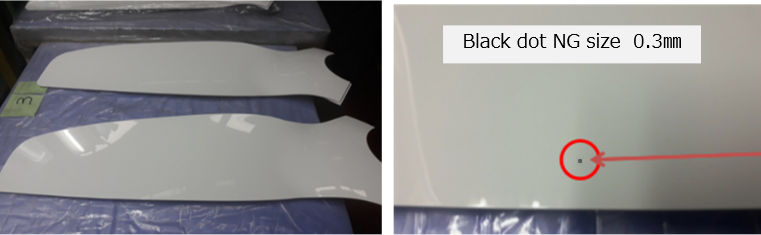

Main problem at molding process is mixing by black dot foreign materials. "ecomaru" prevents occurrence of defective products before it happens by removing foreign materials like burnt resin stuck at tiny spots inside the molding machine and carbonization which are the causes of defects.

■Examples for reduction in defective rate

Black-dot defect rate is reduced from 2.3% => 0.9%

- ・Grade used: ecomaru GWS

- ・Molding machine: 850ton

- ・Molding material: TORAY MABS900 352-A

- ・Molded product: Fan blade

- Significant improvement on the productivity

-

During injection or extrusion molding, "ecomaru" cleanly removes resins and foreign materials left on the screws and heating cylinders of molding machine by regular cleaning. Your molding operation's productivity is significantly improved by getting rid of disassembly cleaning. Defect for color residue can be reduced from fast changing color due to its strong cleaning power.

■Shorter cleaning time for changing the color

- Total cost reduction

- "ecomaru" is the solution to rescue and solve the issues encountered for many years at the plastic molding operations, especially reduction of purging operation time and defect rate. Total cost reduction can be achieved with all of those improvements. You can have all of the benefits like improvement on the productivity, cost reduction from the improvements, reduction of disposal cost from decreasing the defect rate and reduction of purging agent cost due to the dramatic increase in cleaning power.

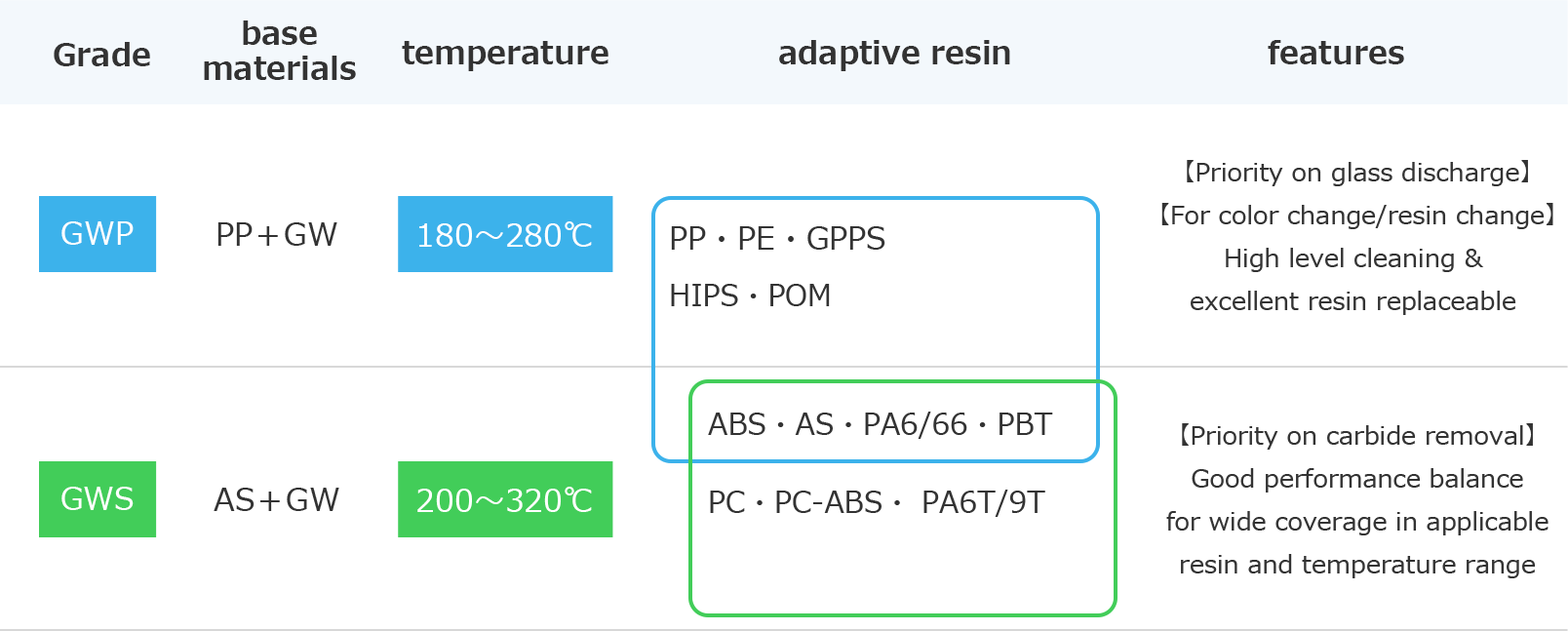

Grade list

| molding machine capacity |

Usage volume guideline (kg) |

|---|---|

| 80 t | 0.2〜0.4 |

| 125 t | 0.4〜0.6 |

| 550 t | 1.5〜2.5 |

| 800 t | 4.0〜6.0 |

| 1250 t | 6.0〜8.0 |

| 3000 t | 15〜20 |

"ecomaru" is manufactured by NANODAX CO., Ltd., and is sold by Koshida Corporation.

For free sample(s) request for your testing and evaluation, etc.,

could you please send your inquiries and requirements

from "ecomaru" manufacturer's site(NANODAX)?

Please click here